Thermoplastic Polyurethane (TPU) / High-Performance Elastomer Materials - DIC Covestro Polymer Ltd.

DCP was established was established in June 2000 as a joint venture between Dainippon Ink and Chemicals (now DIC) and Bayer AG (now Covestro), is responsible for the development of TPU business in Japan. DCP has been leading the Japanese TPU market by importing and selling Covestro’s Desmophane® and Texin® products, and PANDEX® originally from DIC.

TPU, which has excellent basic physical properties and is environmentally friendly, is used in a wide range of fields, including automobiles, home appliances, telecommunications equipment, medical and healthcare, and sporting goods. In addition to enhancing research and development with the aim of expanding the TPU market with quality, our production division has achieved cost competitiveness, high quality, and safe operations through an integrated system from raw materials to compounding, and has meticulously responded to customers' requests.

1

Year of establishment

1

Million JPY Capital

1

%

Covestro share in a JV with DIC

Locations

Company headquarters

Address

KDX Hamamatsucho Place 3F,

1-7-6, Shibakoen, Minato-ku,

Tokyo 105-0011

Phone

03-6403-9107

Fax

Fax 03-3433-0533

Access map

Sales group (Osaka)

Address

3-13-26 Kukuchi,

Amagasaki City, Hyogo Prefecture,

Japan 661-0977

Phone

06-6497-2160

Fax

06-6495-4804

Access map

Sakai Production

Address

1-3, Takasago,

Takaishi, Osaka, Japan 592-0001

Production division

Phone

072-268-0466

Fax

072-268-0402

Technology Development Group

Phone

072-268-3769

Fax

072-268-3784

Access map

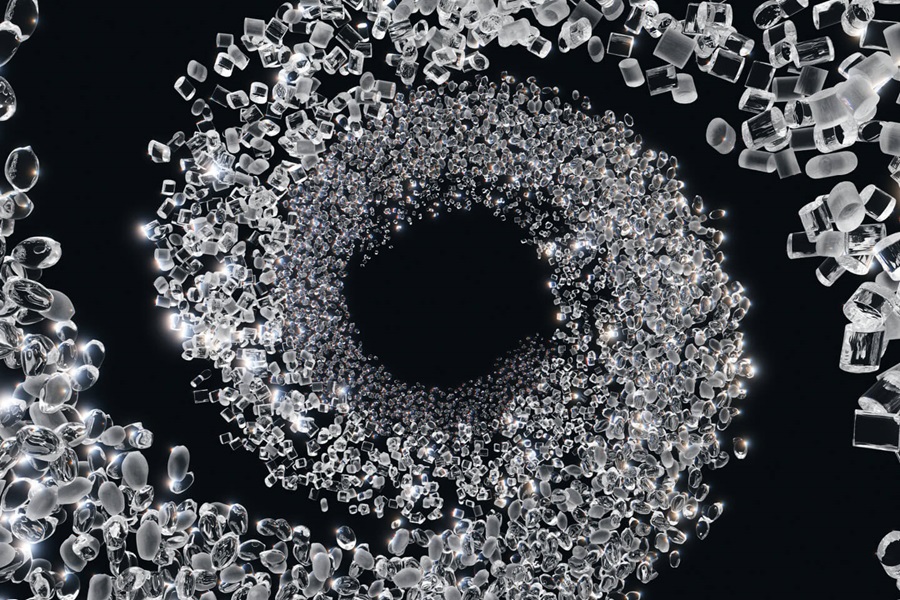

Products: Thermoplastic Polyurethane (TPU)

Thermoplastic Polyurethane (TPU) is a type of thermoplastic elastomer that exhibits characteristics similar to vulcanized rubber and can be molded in the same way as general-purpose resins. With its high elasticity, flexibility, and scratch resistance, TPU is used in a wide range of fields, including living spaces and industrial products. It combines strength with a soft touch, and can be applied in a variety of situations with a rich sense of design. It is also a human-friendly material with excellent recyclability, making it a resin that addresses environmental issues.

- Medical and Nursing Care

- Air mats for nursing care, diaper products, medical gloves, dialysis tubing, arterial, venous, and cardiac tubing, bandage, medical robes, etc.

- Sports Field

- Golf ball skins, sports shoe soles, snowboard skins, ski boots, soccer ball skins, inline skates, etc.

- Automotive

- Interior materials: Instrument panel covers, gear knob covers, console box covers, leather seats, etc.

- Exterior materials: Bumper and side moldings, tail light seals, snow chains, etc.

- Functional parts: Ball joint seals, bellows, spring covers, etc.

- Industrial Products

- Casters, hoses (air hoses, fire hoses), cables, tubes, conveyor belts, cushioning films for packaging, etc.

- Home appliances and others

- Grips for home appliances and tools, camera grips, animal ear tags, watch bands, cell phone part

Product features PANDEX®, Desmopan® and Texin®

- Environmentally Friendly Material

- Recyclable

- Low VOC (Volatile Organic Compounds)

- Halogen-free

- Wide Product Range

- Covers a broad spectrum from rubber-like to plastic-like materials (Shore A hardness 70A to Shore D hardness 70D)

- Various types available to meet required quality standards

- Suitable for medical applications (grades conforming to ISO 10993 Part I biochemical tests and biocompatibility standards)

Product Portfolio

Products Range

| Hardness | Softer | ⟷ | Harder | |||

|---|---|---|---|---|---|---|

| Type | <80A | 80A~89A | 90A~94A | 95A~98A | 55D~65D | >65D |

| Ester (adipate) |

PX.T-1575N PX.T-1877CN (w/Plasticizer) DP.1065AU DP.1075AU |

PX.T-1280N PX.T-1180N PX.T-1185N |

PX.T-1190N PX.T-1490N DP.T-3190N |

PX.T-1195N PX.T-1495N DP.8795A |

– | – |

| Special ester | – |

DP.487 DP.80AHM DPS650 |

|

– | DP.460 | – |

| Ester (lactone) | – |

PX.T-2180N PX.T-2185N |

PX.T-2190N |

PX.T-2195N PX.T-2198N |

PX.T-5965D | PX.T-5070 |

| Ether |

PX.T-8175N PX.T-8375N |

PX.T-8180N PX.T-8185N |

PX.T-8190N |

PX.T-8195N PX.T-8198N |

PX.T-8260DN |

PX.T-8166DN |

| Special ether | – |

PX.T-6880N DP.9385A GMP DP.9388AUFR P05 |

– |

|

– |

|

| Carbonate | – | PX.T-9280N | PX.T-9290N | – | – | – |

| Aliphatic | – |

DP.88385AU DPS307 DP.83085A DPS300 |

– | DP.88395AU DPS302 | – | – |

| Medical | – |

TX.RxT80A TX.RxT85A TX.RxS285 DP.RxT85A |

TX.RxT90A TX.RxS292 |

TX.RxT50D | DP.RxT65D |

TX.RxT76D DP.RxT75D |

|

PX=Pandex®, DP=Desmopan®, TX=Texin® Above are representative examples. We will introduce product numbers that match your molding methods and characteristics. Please contact us for your needs. |

||||||

- Types Available:

- Ester (Adipate) Type:

- Excellent mechanical strength, oil resistance, and chemical resistance

- PANDEX T-1000 Series

- Ester (Lactone) Type:

- Excellent mechanical strength, oil resistance, and chemical resistance

- PANDEX T-2000 Series

- Ether Type:

- Excellent water resistance, mold resistance, and cold resistance

- PANDEX T-8000 Series

- Polycarbonate Type:

- Excellent water resistance and heat resistance

- PANDEX T-9000 Series

- Additionally, a variety of specialized grades are available, including:

- Aliphatic non-yellowing grade

- Aliphatic non-yellowing transparent grade

- Low compression set grade

- Moisture-permeable grade

- Easy Coloring

- Unlike rubber or cast materials, coloring is simple

- Offers colored pellets, special compounds, and masterbatches tailored to customer requirements

- Easy Molding

- Can be processed using general plastic molding methods such as:

- Injection molding

- Extrusion molding (tubes, T-die, inflation, profiles)

- Calendar molding

- Powder slush molding

- Superior Mechanical Strength, Abrasion Resistance, Low-Temperature Properties, and Durability

Product catalogue

Working at Covestro in Japan

With ca. 400 employees, the Covestro team in Japan is working from six sites, including the Tokyo headquarters, production sites in Niihama, Sakai and Tsukuba, as well as two R&D sites in Amagasaki and Kawasaki. Together we deliver the best material solutions to our customers in the local market to make also Japan a brighter place. Functions range from production operators, chemical engineers, sales & marketing and other administrative roles.

A selection of opening positions in Japan are shared here. Why don’t you have a look to see whether there is a match for you and our company?